FOR NEW CONCRETE POURS

Floor Seal Technology’s MirrorCrete system is the most important factor for a sustainable and beautiful polished concrete floor outcome. By now most have seen the negative aspects of slabs that got away. Achieving the required floor flatness of +35 for polishing is mandatory, a plus 50FF is outstanding. It all should start with FST consultation, mix design, placement over-sight, and curing. All components must be an unbroken part of the chain. Specifications that have been cut and pasted is a recipe that will cause concrete placement mistakes ongoing. FST works directly with the Architects and Engineers to design concrete floor slabs for their specific projects that surpass all expectations. A specification is just that, with little or no guidance for modern practices. In addition, the FST TekCrete ready-mix designs can mimic terrazzo and at one third the cost of terrazzo with up to three weeks saved on construction schedules. The MirrorCrete system, delivers the specified polish concrete result every time. MirrorCrete polish concrete diamond tooling is designed for flawless results. The MirrorCrete–Color Match Patch will make any needed repairs and cracks blend with the existing concrete. The MirrorCrete densification and sealing chemical process insure the maximum longevity and stain protection possible for the new polished concrete floors. MirrorCrete–MirrorClean polished concrete maintenance system will preserve the polished concrete for many years to come.

MirrorCrete full circle system of components

- Collaborating with the architect with up-front planning including the concrete place and finish techniques.

- Consulting and creating the Concrete mix design.

- The system includes TekCrete finishing aid, that helps level ready-mix concrete. Shrink compensated additives reducing the need for control joints.

- MirrorCure When combined with mix design will reduce or eliminate cracks and curling at joints. MirrorCure film forming compound reduces overall slab volume shrinkage.

- Oversight concrete placement and supervision. FST collaborates with the concrete placement company directly and throughout installation. FST inspects all edging forms for level and MEP protrusions. No matter what time the concrete is poured FST is onsite to supervise and if necessary, provide needed finishing equipment to achieve the flat concrete floor.

- Matching repairs if needed using MirrorCrete-Color Match Patch. The exclusive invisible repair system for polished concrete.

- Installation of polished concrete using the MirrorCrete proven line of equipment, diamond tooling and process chemicals.

- MirrorClean polished concrete maintenance system.

Natural Polished Concrete Finish

MirrorCure | Special concrete curing technology

MirrorCrete | Proprietary colloidal silica hardener, and densifier

Optional Components

MirrorDye | Concrete colorant for polish compatibility

MirrorSeal | Water, stain and chemical protectant

MirrorCrete-Color Match Patch | Invisible repairs and grouting

MirrorClean | Specialty polished floor cleaner

Projects where MirrorCrete system is NOT used

- Floor Flatness requirements are rarely met.

- Shrinkage and map cracking.

- Wavy surface resulting change orders for extra cutting. Can be six times the budgeted cost to polish.

- Carbonation contamination can occur if not properly placed.

- Extra costs and time for crack repair that will not match.

- Extra costs and time for any other needed repairs that will not match.

- Excessive extra costs and time for grouting a porous surface.

- Substandard concrete polishing results.

- Polished surface that wears out in a truly short time.

- Polished surface easily stains.

- Budget breaking extra costs and time to install adjoining cabinets, door frames, other flooring choices.

The ensuing blame game…

If the concrete is not properly specified and managed, where does the blame lie?

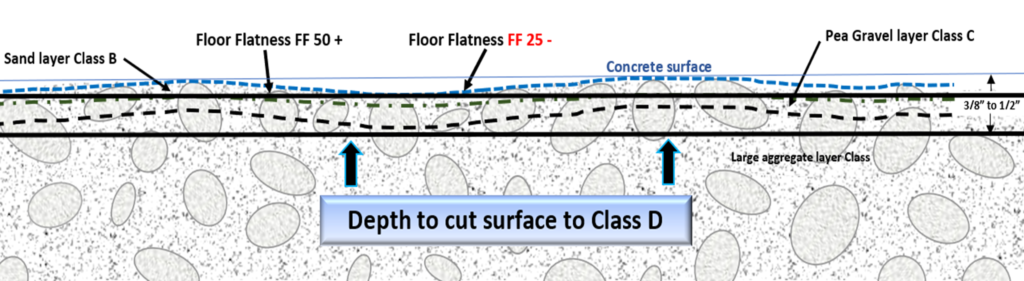

Options for Wavy Concrete.

- Accept the concrete as is. The No cost option.

- Cut to Class C or D. Three to Six times original cost.

- Remove and Replace slab or install a polished concrete overlay cap. Highest cost option.

- FF 25 or Less Polish

- FF 50 or Better Polish

Resources

Below you can view and download our available documents for more information about MirrorCrete.

Product Questions? Contact Us!

Related Projects

Location: Los Gatos, CA

Client: Devcon Construction

Architect: Gensler Architects

Location: Santa Clara, CA

Client: Devcon Construction

Architect: Studio O+A